One tower the initial tower dries the air while the other tower is re generated.

Twin tower heatless air dryer.

The standard cycle time for a heaterless air dryer is 10 minutes for a 40 f dewpoint.

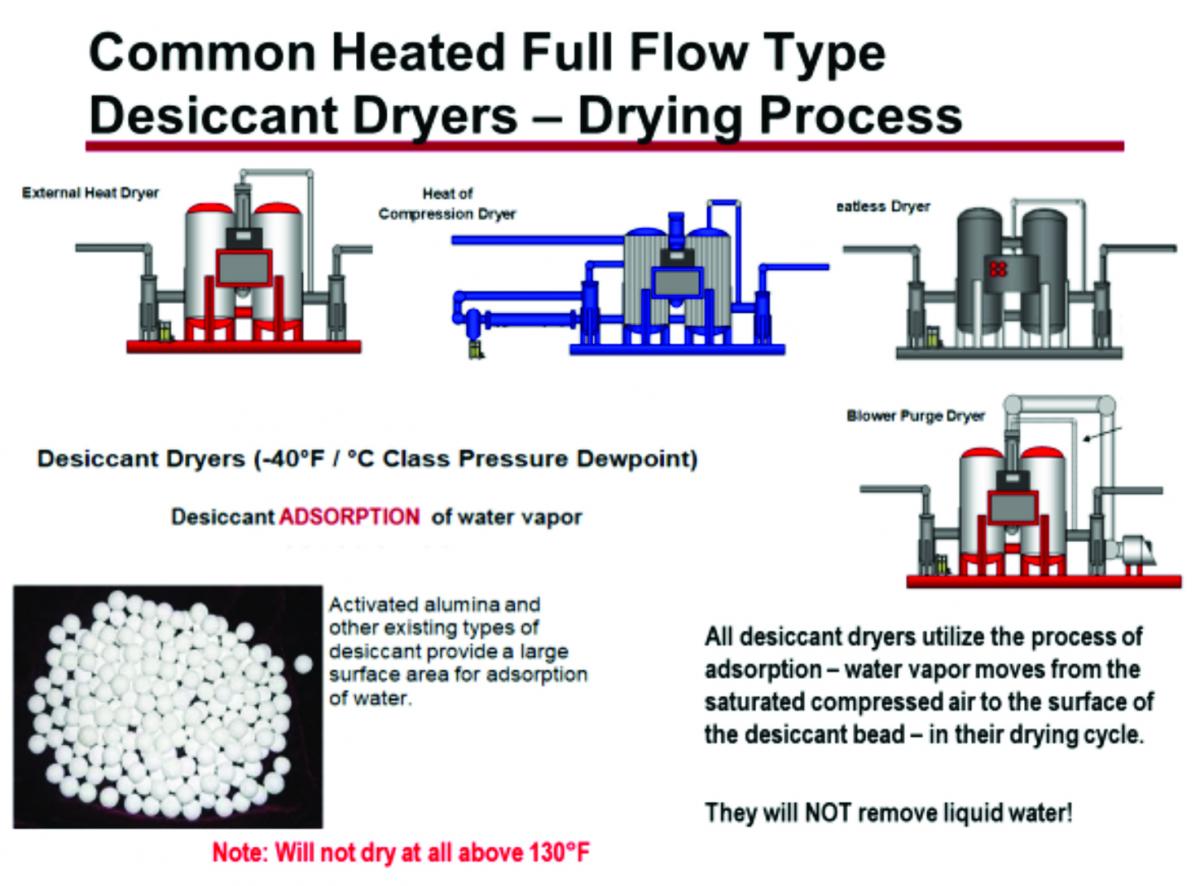

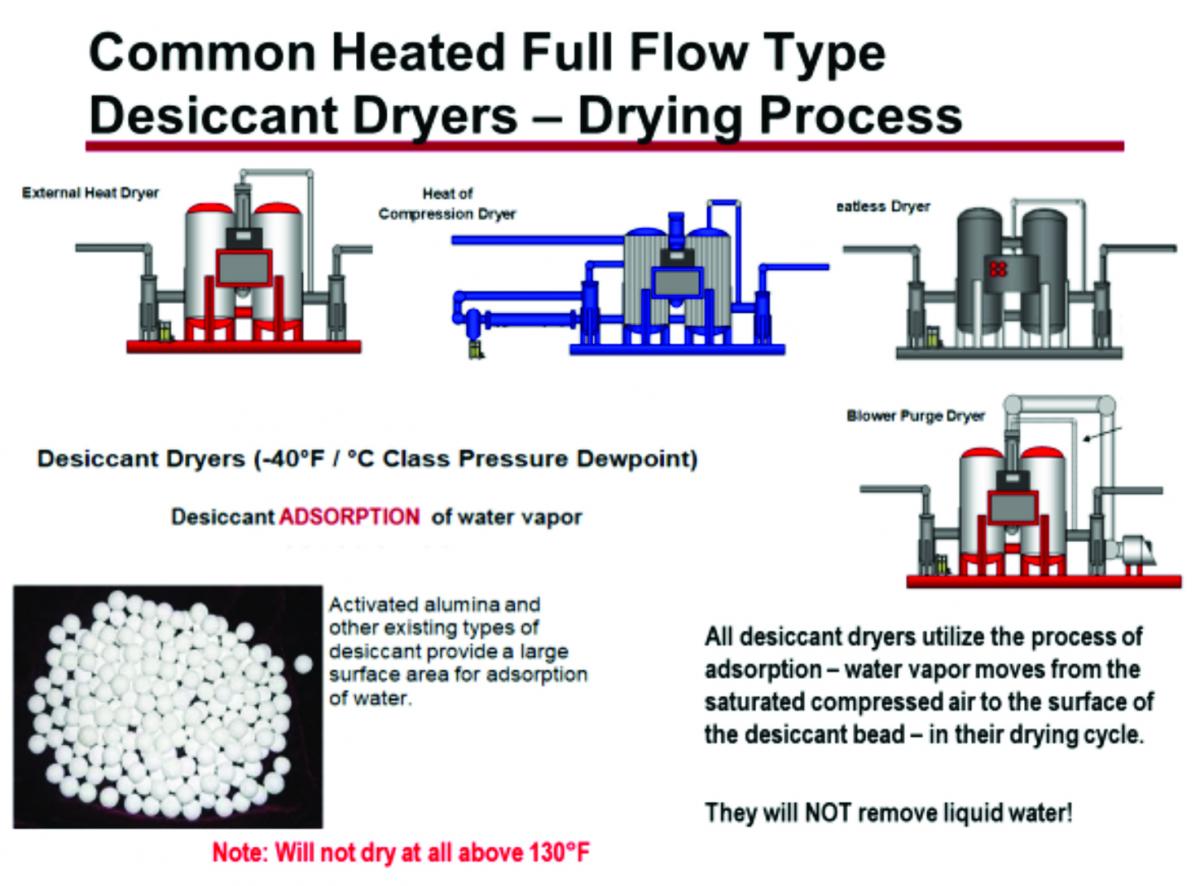

How this happens depends on the type of desiccant dryer.

Parker airtek tw series heatless twin tower desiccant air dryers remove contaminants in compressed air systems using pressure swing adsorption psa technology.

Complete range of twin tower desiccant air dryers regenerative air dryer and other products for al industrial applications.

The dry air then flows through and regenerates desiccant.

Other variations exist for varied dewpoints.

Generon heatless desiccant dryers consist of two towers containing a specialized material that absorbs the water vapor in the saturated compressed air stream.

Parker zander kta series heatless twin tower desiccant air dryers effectively remove contaminants in compressed air systems using pressure swing adsorption psa technology.

A typical heatless dryer includes two towers filled with desiccant activated alumina or molecular sieve.

We are leading supplier for heatless air dryer compressed air dryer.

The simple technology of heatless dryers divert a portion of dried compressed air to an off line tower.

Heatless desiccant air dryers hhs series hhl series and hhe series 40 to 5400 scfm 68 to 9175 nm 3 h hankison s heatless desiccant dryers the hhs hhl hhe series utilizing twin towers filled with premium grade activated alumina hankison heatless dryers are available with three application specific control systems.

Pressure dewpoint of 40 f 40 c and flowrate of 10 6000 scfm depending on model.

Hl heatless desiccant dryers use twin desiccant towers with strategically positioned valves to dry compressed air.

Pressure dewpoint of 40 f 40 c and flowrate of 10 6000 scfm depending on model.

As the air flows through the initial tower the desiccant absorbs moisture its pores capture and hold moisture and the dried air flows out of that tower.

Pressure swing dryers are often called heaterless or heatless dryers because no outside heat is added for the regeneration of the desiccant.

The purge air stream then carries the desorbed water out of the dryer.

Blower purge dryers use a combination of air from an external blower heat and minimal compressed air.

10 6000 scfm standard dewpoint of 40 f.

The amount of time that the saturated air remains in contact with the adsorption material dictates the output air dew point dryness of the product.

Although operating costs run higher than the heated desiccant dryers the hl series requires the lowest capital investment.